Chemical pumps play an important role in many industries. They are able to provide efficient and safe transfer mixing, dispensing and mixing of chemicals. They are specially made to handle corrosive or harsh fluids that cannot be taken care of by standard pumps. Chemical pumps can be classified in two broad types: positive and centrifugal displacement pumps.

Working with reliable chemical pump manufacturers gives you access to high-quality pumps that comply with stringent industry standards. The manufacturers use their knowledge in the production of chemical pumps that are durable and durable, as well as efficient and cost-effective. To stand up to chemicals that can be corrosive or even abrasive they use advanced technologies, materials, manufacturing processes and other methods. It is vital to work with reputable manufacturers who supply pumps that work well and withstand the harshest environmental conditions.

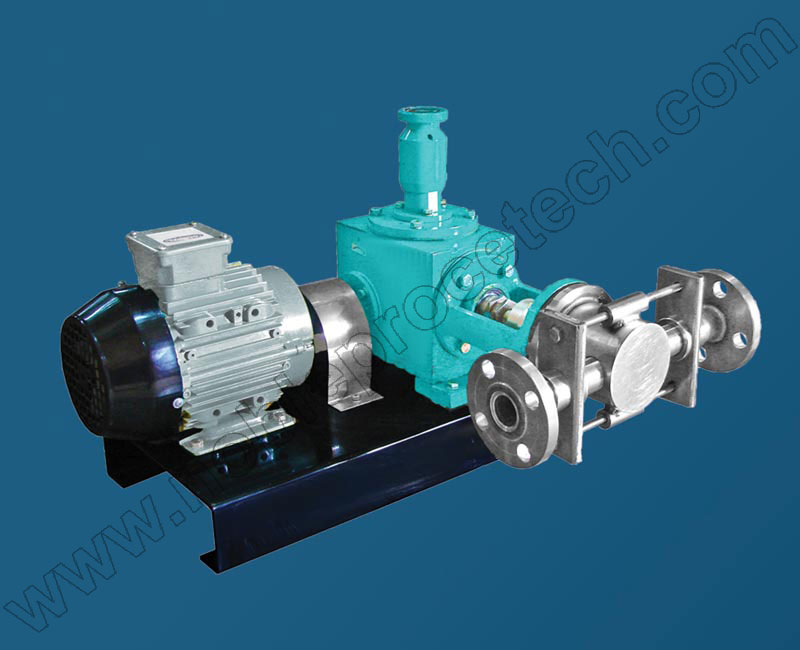

Chemical transfer pumps manufacturers are experts at designing pumps that are designed specifically for fluid transfer applications. They are engineered to deal with a variety of chemicals, such as acetic acid, sulphuric acid as well as sodium hypochlorite and other. With a focus on efficient chemical transfer, pump manufacturers develop pumps with features like corrosion-resistant material seals, leak-proof seals, as well as precise flow control systems. They are designed for seamless, safe and precise chemical transfers. For more information, click chemical manufacturing pump

Chemical pump companies can play a crucial role in ensuring that businesses have the most appropriate pumps to meet their requirements. These suppliers provide a variety of chemical pumps made by reputable manufacturers. They have comprehensive product catalogs, technical know-how and support for customers to help businesses select the best pumps for their specific needs. Chemical pump suppliers offer a variety of options so that companies can pick the best pump for their particular industry.

The significance of dependable chemical pumps goes beyond fluid safeguarding. These pumps play a crucial part in ensuring the integrity of the whole industrial process. If a pump is not functioning properly or is unreliable, it can lead to costly leaks, inefficient processes and even potential dangers. In industries where chemicals are used like chemical manufacturing or petrochemical industry the consequences of a pump failure are often severe.

By investing in reliable chemical pumps businesses can minimize the risks related to handling fluids. They’re designed and manufactured to stand up to the corrosive qualities of different chemical substances, making sure that they will function consistently and effectively over time. They are constructed with strong materials, high-end seal mechanisms and exact flow control. All of these elements contribute to a safe and reliable flow of fluid.

In most cases, chemical pumps that are reliable include maintenance and support services. Manufacturers and suppliers understand the critical nature of these pumps and will provide technical assistance, spare parts availability, and regular maintenance tests. This proactive approach can help identify any issues that could arise and resolve them before they escalate. This makes sure that the pump is reliable and downtimes that are not planned are minimized.

Chemical pumps are used in many industries including food processing, petrochemicals as well as chemical manufacturing. These pumps are essential for fluid transfer, mixing and dispensing in these fields. Chemical pumps are widely employed for high-temperature heaters as well as in off-site applications at refineries. Chemical pumps are an essential tool for industrial processes due to their versatility and ability handle challenging fluids.

Think about factors like fluid type, the flow requirements, and operating conditions when selecting the right chemical pump. Chemical pump suppliers and manufacturers provide support and guidance on how to select the right pump for the specific application. Prioritizing safety, efficiency and reliability is essential when selecting a chemical machine to reduce the risk of danger while maximizing productivity and minimizing downtime.

Chemical pumps are used in refineries to serve a variety of uses. They play a crucial role in off-site operations and contribute to the secure and efficient transfer of chemicals in different contexts. It could be transporting corrosive liquids to storage facilities, aiding loading and unloading tanker trucks or aiding repair and maintenance activities Chemical pumps are essential for ensuring that smooth operations are carried out beyond the refinery’s limits. The dependability, durability, and the specialized characteristics of these pumps make them essential equipment for applications off-site in which handling chemical substances that are corrosive or abrasive requires precision, efficiency, as well as security. By investing in top-quality chemical pumps and partnering with trusted suppliers and manufacturers, refineries can maintain a strong foundation for their off-site operations and enjoy an efficient and safe chemical transfer in diverse settings.